How Much Does Heat Pump Installation Cost?

Most homeowners spend $6,500 to $12,000 installed for a new heat pump, with a national average near $9,000. Your total includes the system plus installation — labor, basic materials, line sets, pads or hangers, and startup. Prices vary by type (air source, ductless, or geothermal), capacity (tonnage), efficiency, and any electrical or ductwork changes.

Heat pumps are primarily electric systems, regardless of type. Air-source and ductless mini-split heat pumps run entirely on electricity, using it to transfer heat rather than generate it. Geothermal heat pumps are also electric, drawing stable ground energy through buried loops. Some newer systems use propane (R290) only as a refrigerant — not a fuel source — so the heat pump still operates as a fully electric system.

Heat Pump Types: Total Cost and Best Fit

| Type | Typical Cost | Best For | Notes |

|---|---|---|---|

| Air Source (Ducted) | $6,500 to $12,000 | Homes with ducts | One system for heating and cooling; strong value in most climates with the right efficiency. |

| Ductless (Mini-Split) | $2,000 to $6,000 per single-zone; $8,000 to $15,000 multi-zone | Homes without ducts, additions, hard-to-heat rooms | Flexible, efficient zoning; great comfort control. |

| Geothermal (Ground-Source) | $15,000 to $35,000+ | Long-term homes, high energy savings goals | Highest upfront cost, lowest operating cost; durable underground loop. |

Air Source

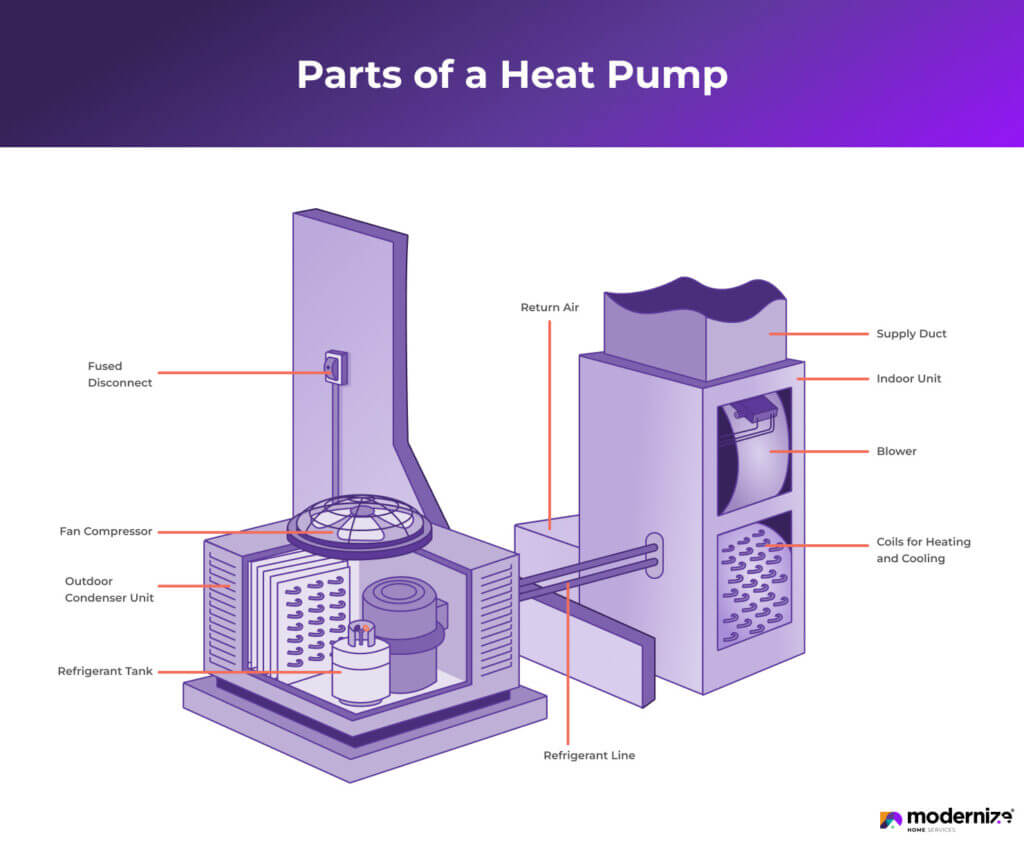

Air-source heat pumps use an outdoor unit and your home’s ducts to move heat — bringing heat in during winter and sending it out in summer. They replace both a furnace and central AC in one system and work well in most homes with existing ductwork.

- Average Cost: Expect to pay $7,500 to $11,000 (extremes $4,500 to $12,000, based on size, efficiency, and duct condition).

- How It Works: A ducted air-source heat pump moves heat between your home and the outside air using refrigerant and a compressor. It heats in winter and cools in summer.

- Why Choose It: Benefits include whole-home comfort with one system, good efficiency, and often the best value if you already have usable ducts.

- Why Avoid It: In very cold climates, you may need a cold-climate model or a backup heat source. Leaky or undersized ducts add cost.

Ductless

Ductless heat pumps connect one outdoor unit to one or more small indoor heads, so each room or zone has its own thermostat. They’re ideal for homes without ducts, additions, or hard-to-heat spaces.

- Average Cost: Expect to pay $3,000 to $8,000 for a single-zone, $9,000 to $15,000 for multi-zone systems (two to four or more rooms).

- How It Works: An outdoor unit connects to one or more small indoor heads. Each zone has its own thermostat for precise control.

- Why Choose It: No ducts required; excellent for retrofits, additions, bonus rooms, and homes that need different temperatures by room.

- Why Avoid It: Multiple indoor heads raise upfront cost and add wall units to your decor. Whole-home setups can cost as much as ducted units.

Geothermal

Geothermal heat pumps move heat to and from the ground using buried piping loops, where temperatures stay steady year-round. They deliver very high efficiency and low operating costs, with long life for the underground components.

- Average Cost: Expect to pay $20,000 to $40,000, but extremes can be much higher or lower.

- How It Works: Geothermal heat pumps use stable ground temperatures via buried loops to move heat. They’re extremely efficient in both heating and cooling.

- Why Choose It: Ground source heat pumps offer the lowest operating cost, long equipment life, quiet, and excellent comfort — ideal for long-term homes.

- Why Avoid It: Expect high upfront prices and longer installation times, and you’ll need yard space or drilling access.

Cost to Replace Heat Pump and Air Handler

Replacing the outdoor unit and the air handler together typically runs $8,000 to $15,000 installed for a ducted air-source system. Replacing both ensures matched components for efficiency, reliability, and warranty coverage.

Heat Pump Cost Q & A

Get answers to the most common questions homeowners ask about heat pump pricing.

How Much Does a 3-Ton Heat Pump Cost?

A 3-ton ducted air-source heat pump (36,000 BTU) usually costs $9,000 to $13,000 installed, depending on efficiency, brand, and any duct or electrical work. Equipment alone often costs $3,000 to $6,000.

How Much Does It Cost to Replace a Furnace With a Heat Pump?

Expect to pay $7,500 to $15,000 installed for a ducted conversion from furnace to heat pump using existing ducts in good condition. Add $1,500 to $5,000 if you need electrical panel upgrades, new ducts, or significant repairs.

How Much Is a Heat Pump for a 2,000-Square-Foot Home?

Many 2,000-square-foot homes need about 3 to 4 tons, depending on insulation, windows, and climate. The typical installed cost for this size is $8,000 to $14,000 for a ducted air-source system. Ask your contractor for a Manual J load calculation to size it correctly.

How Much Does a Heat Pump Cost According to Reddit?

One user reported that two HVAC contractors provided quotes within the $30,000 to $35,000 price range to replace a forced-air furnace system with a heat pump. A homeowner in the same thread said their 18-SEER2 heat pump cost $25,000. A final commentor reported paying $9,500 after utility rebates.

A homeowner from Georgia was quoted $10,000 to $12,000 to replace a 13-year-old heat pump. From the same thread:

“I was just quoted $23k for a 36kBTU cold climate ducted heat pump install. After rebates it’s $17k.”

“Mine was $6000 installed, already existing ducts. 1200 sqft home, single Rheem unit.”

Cost of Running a Heat Pump

Heat pumps usually cost less to run than electric furnaces and can compete with gas furnaces depending on utility rates and climate. Below is an illustrative monthly heating cost snapshot for a typical home with a well-sized heat pump. Your bills will vary with house size, insulation, thermostat settings, and local rates. See the table below for typical costs during cooler seasons in the U.S.

| Month | Northern U.S. | Midwest | Mid-Atlantic | South |

|---|---|---|---|---|

| January | $220 to $360 | $170 to $300 | $140 to $240 | $90 to $170 |

| February | $190 to $320 | $150 to $260 | $120 to $210 | $80 to $150 |

| March | $130 to $240 | $110 to $200 | $90 to $160 | $60 to $120 |

| April | $60 to $140 | $50 to $120 | $40 to $100 | $30 to $80 |

| October | $70 to $150 | $60 to $130 | $50 to $110 | $30 to $80 |

| November | $150 to $280 | $120 to $220 | $100 to $190 | $70 to $140 |

| December | $200 to $340 | $160 to $280 | $130 to $230 | $90 to $170 |

What Affects Heat Pump Costs?

- Capacity (Tonnage): Larger systems cost more.

- Efficiency Ratings: Heat pumps with higher efficiency ratings cost more upfront but can lower monthly bills.

- Type and Layout: Pricing varies based on whether the heat pump is ducted, ductless, or geothermal — and how many zones you need.

- Ductwork Condition: Leaky, undersized, or uninsulated ducts add repair or replacement cost.

- Electrical Work: Panel upgrades, new circuits, or disconnects will add to your costs.

- Controls and Features: Variable-speed compressors and smart thermostats improve comfort and efficiency but can raise prices.

- Home and Climate: Insulation, windows, and local weather shape both size and efficiency needs.

- Permits and Labor: Local code requirements, crane access, and line-set lengths affect installation time and price.

- Incentives: Check for utility rebates or local programs to improve payback.

How to Save Money on Heat Pump Installation Costs

- Get Multiple Itemized Quotes: Ask for model numbers, tonnage, efficiency ratings, and everything included — equipment, labor, permits, electrical, and haul-away.

- Right-Size the System: Require a Manual J load calculation. Oversized systems short-cycle; undersized systems struggle in cold snaps.

- Fix Ducts First: Seal and insulate ducts in attics or crawl spaces to cut bills and reduce the size you need.

- Choose the Right Efficiency: Pick the sweet spot for your rates and climate. Ultra-high efficiency is great, but a step down may offer better payback.

- Plan Your Zones: For ductless, design zones you will actually use. Fewer, well-placed heads can trim thousands.

- Bundle Work: Replacing the heat pump and air handler together ensures a matched system and can lower labor.

- Ask About Rebates: Utilities often offer cash incentives for qualifying heat pumps or duct sealing — ask your contractor to help file.

Heat Pump Repair Cost vs. Replacement Cost

If your system is acting up, heat pump repair costs can range from a relatively minor service call to a more expensive fix involving major components. The challenge is that a repair quote doesn’t always reflect the full picture — age, efficiency, and how often issues are popping up all matter. Comparing repair pricing with replacement costs can help you decide whether a quick fix makes sense or if investing in a new heat pump will deliver better reliability and long-term value.

What Are the Best Heat Pump Brands?

Here’s what you’ll pay, on average, for top heat pump brands.

| Brand (Examples) | Typical Unit Cost* |

|---|---|

| Trane / American Standard | $3,000 to $6,500 |

| Carrier / Bryant | $2,800 to $6,200 |

| Lennox | $3,000 to $6,800 |

| Rheem / Ruud | $2,400 to $5,500 |

| Goodman / Amana | $2,200 to $5,000 |

| Mitsubishi Electric (ductless) | $2,500 to $6,000 per outdoor + heads |

| Daikin (ducted and ductless) | $2,500 to $6,000 |

*Unit cost only — installed prices depend on labor, materials, electrical work, and design.

Heat Pump Replacement: What to Know Before Calling a Contractor

- Ask for a Manual J Load Calculation: Correct sizing is essential for the most energy efficiency.

- Confirm Scope and Permits: Find out who pulls the permit, handles inspections, and registers the warranty.

- Check Ducts and Electrical Early: Fixing these first avoids change orders later.

- Verify Brands and Model Numbers: Your proposal should list exact equipment and efficiency ratings.

- Review Warranty and Service: Parts, labor, and who services the system locally.

Need a hand? Modernize can connect you with pre-vetted local pros for itemized quotes and expert guidance.

Compare top-rated HVAC pros in your area.

Read real homeowner reviews, explore qualifications, and view promotions. Modernize makes it easy to browse professionals and find one that will be perfect for your project.