What is Safety Glass?

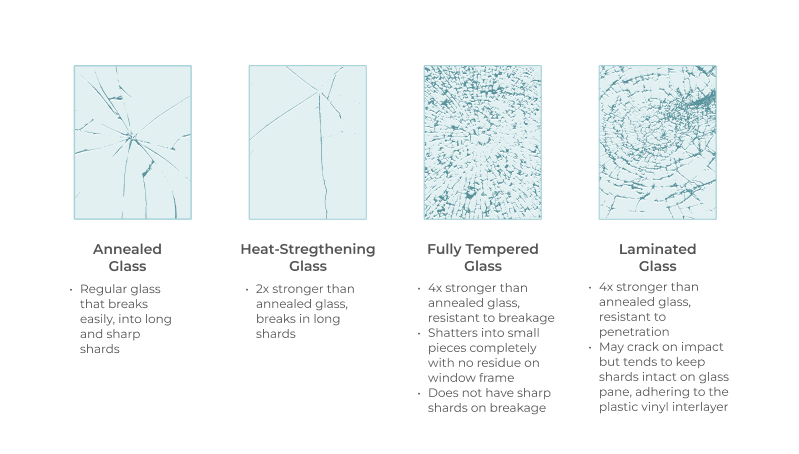

Safety glass is an umbrella term for glass that’s specially manufactured to increase its tensile strength. The two most common types of safety glass are tempered and laminated glass, though there are several other types of safety glass used in residential and commercial settings.

Whether you know it or not, you have safety glass throughout your home. The International Residential Code, which regulates construction and plumbing, electrical, heating, mechanical, and energy systems for homes that are three stories or less, requires the use of safety window glass in many areas of your home. Safety glass can be as much as five times stronger than a pane of regular glass and is usually tempered or laminated.

This toughened glass increases safety because the glass won’t shatter into sharp shards if it breaks from a hard impact. It is made from using different manufacturing processes, such as heat treating and rapid cooling, or lamination under high pressure and heat.

Safety Glass Costs

Be prepared to pay more for safety glass. Tempered glass costs between $12 and $50 per square foot. If you are considering replacement windows using tempered glass, they will run 15% to 50% more than standard glass.

Because laminated glass uses two panels and a vinyl interlayer, it will cost even more, from $100 to $400 per square foot depending on glass thickness, color, and edging choice.

Both glass types are much more resistant to scratches and breaks, which will reduce ongoing repair costs over their lifespan.

Safety Glass and Security

Safety glass is also called securing glass because it can provide an increased level of security for your home. A laminated glass window, for instance, is nearly impossible to get past even when broken because of the thick resin layer used to bond the inner and outer panes of glass.

Modernize created this comprehensive guide to safety window glass to provide homeowners with all the information they need to know about installing security glass in their homes, as well as the pros and cons of safety window glass and also provided insight into how they are made and the benefits they offer. In this next section you will also learn more about the difference between tempered and laminated safety glass.

What is Tempered Glass?

Ohio resident Harold McMaster didn’t invent the process of tempering glass, but he was the first to commercialize it in the United States.

Tempered glass is made by heating glass to around 1,200 degrees Fahrenheit and then rapidly cooling or quenching it with cold air for a few seconds. This process shocks the outer surface of the glass, which compresses the edges, and places tension on the inner layer as it tries to retreat. The result is toughened glass that’s roughly five times stronger than annealed (untreated) glass.

Tempered glass has many well-known properties, including:

- Much safer than annealed glass because it won’t break into dangerous shards.

- Stronger than normal glass

- Scratch resistant

- Heat resistant up to 470 degrees Fahrenheit

Some of the many uses of tempered glass are the side windows in automobiles, as well as shower doors, railings, cell phone screens, display cases, lighting fixtures, and of course windows and sliding patio doors.

What is Laminated Glass?

Credit French chemist and inventor Edouard Benedictus with inventing laminated safety glass. In 1903 Benedictus accidentally dropped a glass flask he was tinkering with, and instead of shattering the vessel held together due to the plastic mixture that was inside it. His version of safety glass was first used in WWI as a face shield for gas masks, and by the 1920s it was standard for automobile windshields.

Today, laminated glass is made by bonding layers of glass together using polyvinyl butyral (PVB) resin, heat and pressure – that’s why it’s also called sandwiched glass. The PVB resin holds the glass together if it breaks, which reduces the risk of cuts from broken pieces and also increases building security since the window maintains its shape and form even when broken.

Laminated glass has many benefits:

- It is nearly impossible for an intruder to get past a laminated glass window due to the thick layer of PVB resin.

- They dampen outside sounds

- It blocks most ultraviolet rays from penetrating your home

- It has exceptional durability and longevity

- Sheets of laminated glass can be heat treated, annealed, patterned, wired or tinted, giving you limitless design possibilities.

- In the event of a natural disaster such as a hurricane or tornado, the window may break but the glass will stay attached to the resin interlayer and not become dangerous flying shrapnel.

Common uses for laminated glass include vehicle windshields and residential windows and sliding glass doors, as well as interior spaces as stair balustrades and paneling.

What is Wired Glass?

As the name suggests, wired glass has a wire mesh embedded throughout the pane during the manufacturing process. The wire mesh reinforces the window just like rebar greatly increases the tensile strength of concrete.

In addition to added strength, wired glass has many benefits:

- If the glass breaks it will adhere to the wire mesh, which provides increased safety.

- Since the glass won’t be displaced if broken, wired glass is classified as a cost-effective type of fire-resistant glass.

- It can be made with obscure glass for enhanced privacy.

- The wire mesh can be made in an array of patterns for enhanced visual appeal.

Wired glass, also called meshed glass, can be found in exterior uses such as windows and doors, or interior spaces such as partitions, dividers and window transoms. It enjoys a special place in construction as a fire-rated building material for non-hazardous locations due to its special properties. Wired glass made from annealed glass will crack at 212 degrees Fahrenheit, but the wire holds the glass together. In greater temperatures the glass softens and heals the cracks, which prevents flame, smoke and heat from passing.

More Types of Safety Glass

While we have highlighted the most common types of safety glass and their uses, there are a few others worth noting. Additional forms of safety glass include:

- Multi-layered glass. Multiple layers of glass are bonded together, which further enhances the benefits that come with laminated glass.

- Bullet-resistant or armored glass. Bullet-resistant glass and armored glass provide ballistic protection depending on thickness and layers of lamination. Thicker glass will better stop a bullet, but it also reduces light transmission. This type of glass is typically made from acrylic, polycarbonate, or glass-clad polycarbonate.

- Engraved glass. This type of glass is etched or French embossed to add increased visual appeal to the glass. Engraving is done using diamond scribing, stippling, or with a laser.

Safety Glass Applications

Safety glass is already used in many parts of your home, including your shower door, refrigerator shelves, and glass cookware. In residential and commercial buildings, safety glass is used for windows, doors, skylights, stair balustrades, and the access panels for fire safety or defibrillation equipment. Toughened glass is also used in tabletops, cabinet panels and shelves and fireplace doors.

As noted in the opening of this guide, safety glass is required in many places of your home. All panels in fixed or moving glass doors must be made from safety glass. Same with any glass that’s within two feet of a door, or windows that are larger than nine feet square. Some cities – earthquake-prone San Francisco, for instance – have imposed additional requirements for the use of safety glass in residential applications.

Compare top-rated windows pros in your area.

Read real homeowner reviews, explore qualifications, and view promotions. Modernize makes it easy to browse professionals and find one that will be perfect for your project.