Are you doing an HVAC project?

Modernize can pair you with three to four pros in your area, so you can compare options and save time and money.

As weather turns colder and the year moves from the worry-free summer months, it’s time to consider your heating system and any maintenance it requires. Boiler systems are known for their efficiency and their reliability, but only when maintained and operated properly. There’s a good chance there are some key maintenance tasks you aren’t completing, and that your system isn’t running as well as it could be. Take some time to learn the steps you can take to make a real difference, and hopefully keep your boiler operating effectively for much longer.

Boiler Maintenance Essentials: Keeping Your Heat Source in Top Shape

Regular boiler maintenance is crucial for ensuring its longevity and efficiency. By scheduling annual inspections, checking for leaks, maintaining proper water levels, and clearing out any obstructions in vents and flues, you can prevent most common boiler issues. It’s also wise to listen for unusual noises and to monitor the boiler’s pressure gauge to catch potential problems early. Adopting these preventative habits not only helps avoid unexpected breakdowns but also keeps your boiler running smoothly, ensuring a warm and cozy home environment.

Examine the Vent and Chimney

Both the vent connection and chimney of a boiler will deteriorate with time — which is why it’s important to make sure neither one is suffering from a leak and that they’re in good working order. Look for any holes or broken connections along the chimney and look closely at the place where the vent connects to the boiler unit to be sure it’s all intact. Just visually checking each of these systems a few times a year will help you gauge when problems are going to arise and when work needs to be done.

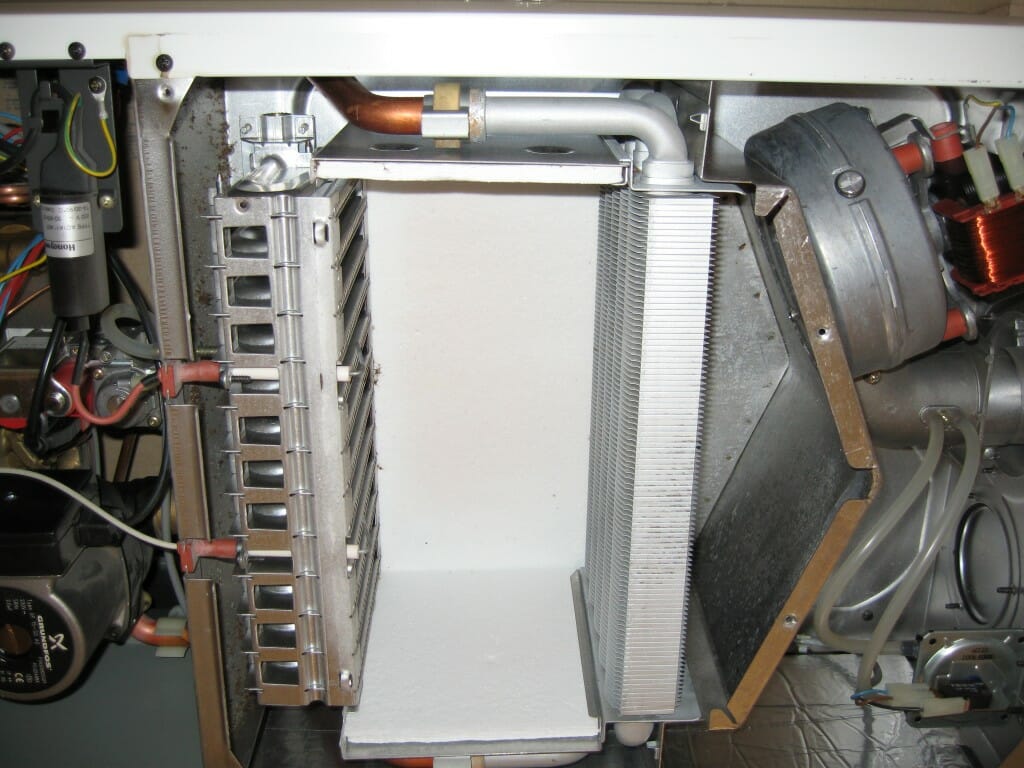

Check the Heat Exchanger

If you’re suffering from a boiler leak, nine times out of ten it’s coming from the heat exchanger. The exchanger is the most prone to leaking of the bunch, and that’s why it’s important to visually inspect it whenever you remember to. Look all around the heat exchanger of your system to see if there are any minor leaks. You can also look for small spots of water around the exchanger during or after operation. If you notice a small pool of water, there’s a good chance the exchanger has to be replaced, and it’s important to make that replacement before the leak grows larger and leads to water damage.

Flush out the Boiler

During regular operation, rust and other debris builds up in the boiler system of your home. Over time this debris can lower the efficiency of the system and even clog it up in some instances. That’s why it’s so important to flush it out on a regular basis as part of your boiler maintenance process. To flush out the boiler, start by opening up the valves on the radiators and convectors to let air into the system. Have buckets ready to catch any water that comes out.

Turn off power and your water supply to make sure the system is ready to be flushed. You can cut power to the boiler through your breaker box. It’s dangerous to work on the system with the power still on. Connect your garden hose to the drain cock of the boiler. Most come with a hose fitting, so it should be easy to screw it tightly onto the system. Run that hose to a large bucket or bathtub to drain out the water and debris.

Walk upstairs and open up the vent valves on the radiator to let air into the pipes. The air will allow water to bleed through the boiler system and out the drain hose. Turn on the supply of water to your home and it will begin flushing through the system. Wait until water stops draining and close the drain cock and the vents.

Find the Right Contractor for Your HVAC Project

Whether you’re ready to begin your project now or need some expert advice, our network of contractors are here to help. With a few simple questions, we’ll find the best local professionals for you

Water will continue flowing into the boiler system until it’s properly pressurized, but only if your system has a pressure-regulating valve. If it does not have a pressure-regulating valve, you’ll have to let air out of each convector of your system until the boiler reaches its ideal pressure level. This is usually only necessary on systems that are quite old.

Lubricate the Circulating Pump

The circulating pump of a boiler heating system is responsible for moving all the water around the system. If the pump fails, effective home heating won’t be possible any longer. That’s why it’s vital to make sure that pump continues to run and function properly. The best way to do that is by lubricating the circulating pump at least once a year. This can be accomplished by taking a 3-in-1 oil and pouring it into the oil cup of the system. The oil will penetrate down into the pump and help keep it from grinding and sticking as it operates.

Get Help from an Expert

Sometimes you just have to call in for expert boiler maintenance help. Boiler systems are quite expensive, and they’re very reliable when maintained properly. That’s exactly why it makes sense to call in a pro to do some maintenance for you if you aren’t comfortable with all the procedures, or if you simply don’t feel like doing the work.

Adjust the Boiler to Operate Efficiently

Now that you know how to maintain your system, it’s time to spend a few minutes adjusting your boiler settings to not only bolster efficiency, but also to cut down on the wear of the system a bit as well. These adjustments are designed to limit the cycling that a boiler does. If your boiler is constantly kicking on and off in a cyclical pattern you’re not running very efficiently, not only that, but you’re likely creating uncomfortable hot and cold spots in your home. To fix the issue, you should set the burner “On” point within just a few PSI on a steam boiler or a few degrees Fahrenheit on a hydronic system, to the “Off” point. What this does is stops the boiler from running at full flame almost completely, and forces it to run at half or ¾ flame nearly continuously.

Instead of running at full blast until hitting the temperature wall and then shutting back off again, the boiler will run at full blast to get up to temperature, and then the flame will fluctuate slightly to maintain the temperature without ever going out. Running constantly is better for the boiler system, and it’s a whole lot more energy efficient.

It’s important to realize that not every boiler can be set up in this manner — some boilers that are older or cheaper are outfitted with a less-capable pressure control, and in those instances the pressure control might have to be upgraded to achieve a constant flame.

Take care of your boiler with regular boiler maintenance and you’ll enjoy more than a decade of reliable heat from the system. Just be sure to follow these standard maintenance tasks and you should minimize any repairs or problems that you run into with your system.

Find the Right Contractor for Your HVAC Project

Whether you’re ready to begin your project now or need some expert advice, our network of contractors are here to help. With a few simple questions, we’ll find the best local professionals for you

Reviews from Real Homeowners

Welcome to Homeowner Resources! We are the Modernize blog. Modernize pairs more than 3 million homeowners a year with pre-vetted contractors in their area. This blog started because we believe homeowners should know everything about their homes, from how their HVAC works to which front door colors they might love. On Homeowner Resources, you can find information on every part of your home, right down to how you can negotiate with contractors to get the best price. Here's more about the blog.

Need a contractor? Learn more about how Modernize finds the right pro for you.